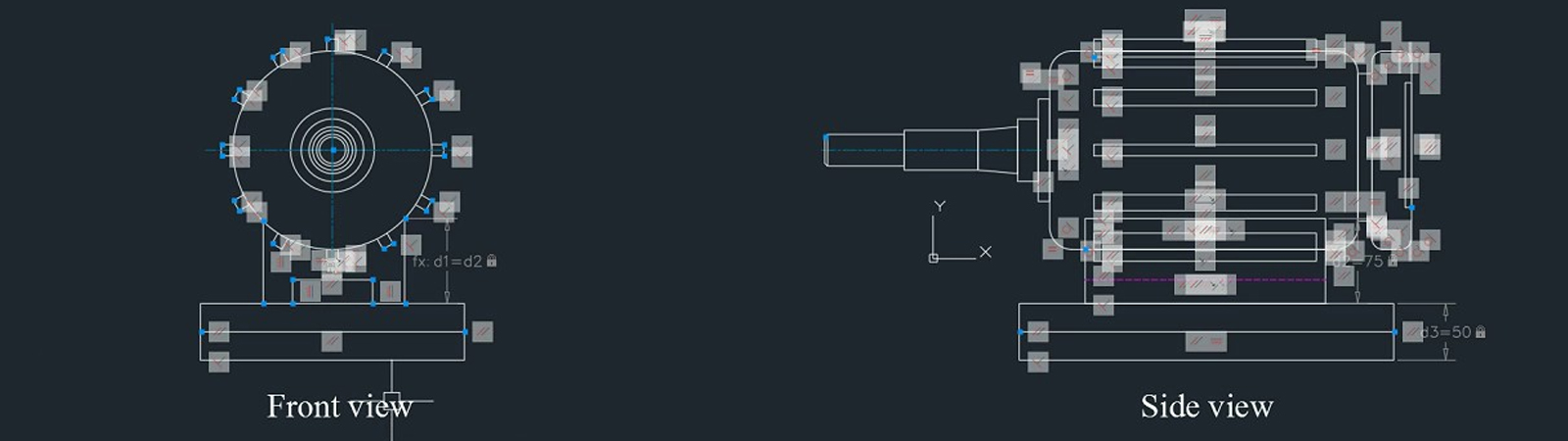

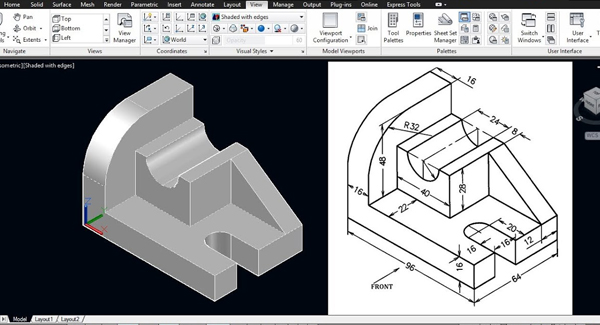

AUTOCAD

It is a mechanical design software used for manufacturing. AutoCAD Mechanical engineering design software which is used for manufacturing products for acceleration of mechanical CAD process in AutoCAD environment.

AutoCAD Mechanical draws the best of AutoCAD in the alignment of industry-specific libraries of tools and parts, making it a must learn for those who are involved in design and construction of the machinery.

At the earliest stages of a design project, mechanical engineers can use AutoCAD to start sketching ideas and analyzing them to determine the best solution for a given problem. The software makes the process quick and easy; it eliminates the need to draw new blueprints for each version of an idea and simplifies redesigns. The software additionally helps interpret these designs, locating flaws, errors and inconsistencies the mechanical engineer might miss. Alternatively, the mechanical engineer can use AutoCAD to determine the source of a malfunction in an existing product by putting in the specifications and allowing the software to find the problem, allowing the engineer to be more efficient by going straight to the problem and finding a fix.

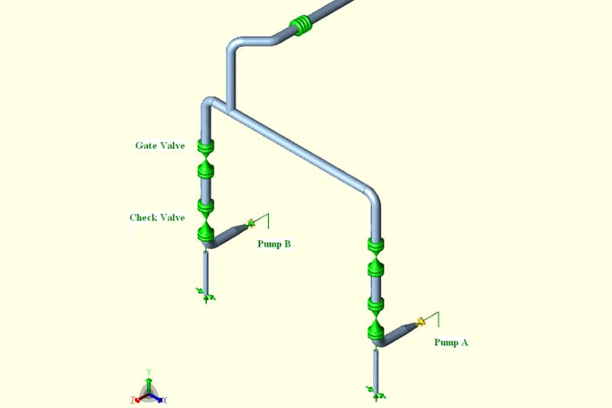

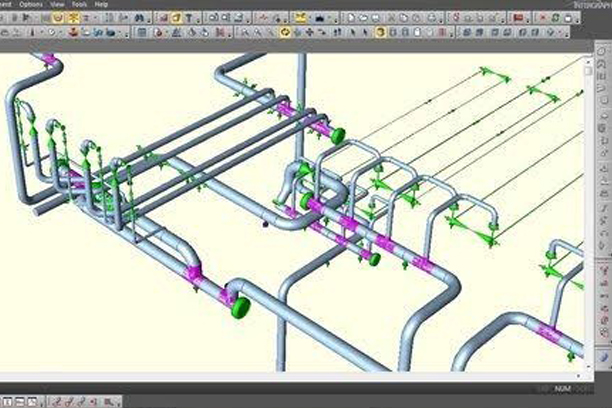

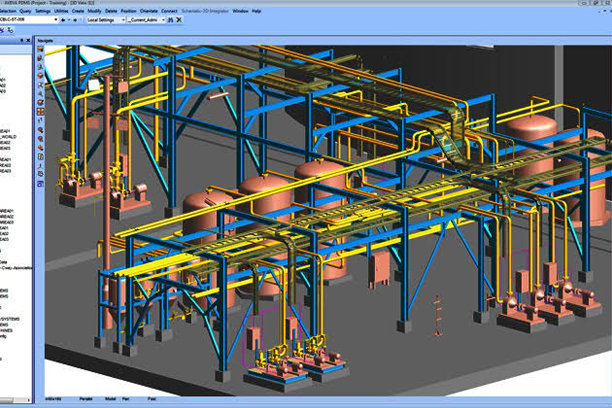

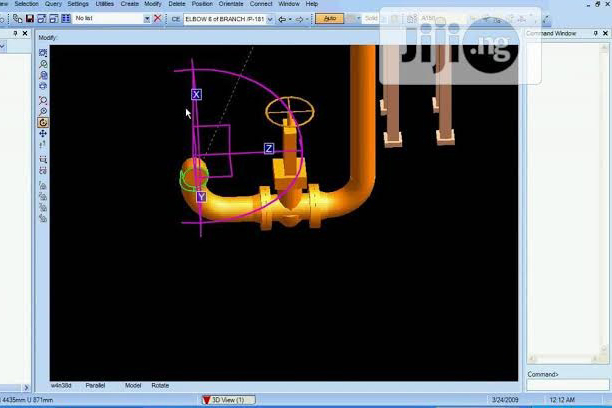

PDMS

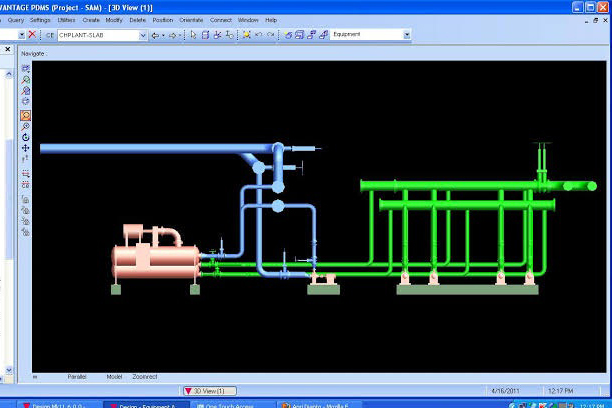

PDMS (Plant Design Management System) as it is known in the 3D CAD industry, is a customizable, multi-user and multi-discipline, engineer controlled design software package for engineering, design and construction projects in offshore and onshore.

Piping Design & Engineering Training course educates the participants on the fundamentals and designing of piping system components and equipments. Through this piping engineering course the candidates develop analytical and designing skills to ensure that the planned system delivers desired function.

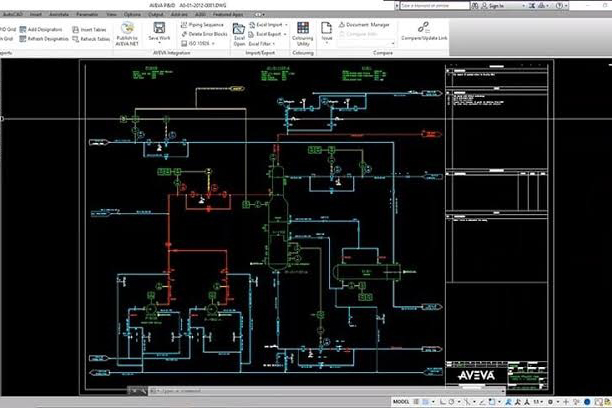

Developed by AVEVA, Plant Design Management System (PDMS) software is used for exploring the concepts practically. PDMS is a 3D CAD customizable software for construction and engineering projects. Delivering training through AVEVA PDMS builds the proficiency in the candidates to develop 3D plant design for all sizes of plant project, ranging from minimal upgradation to new installations of unlimited complexity.

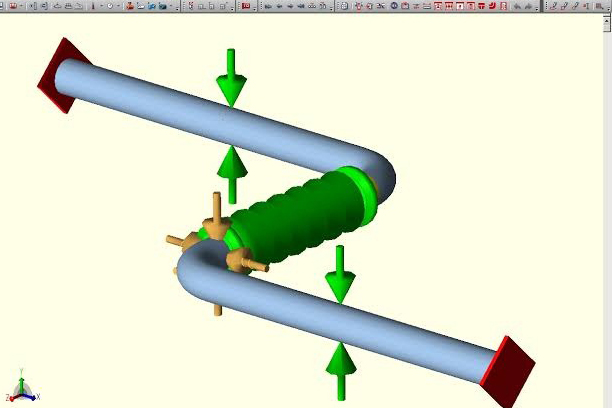

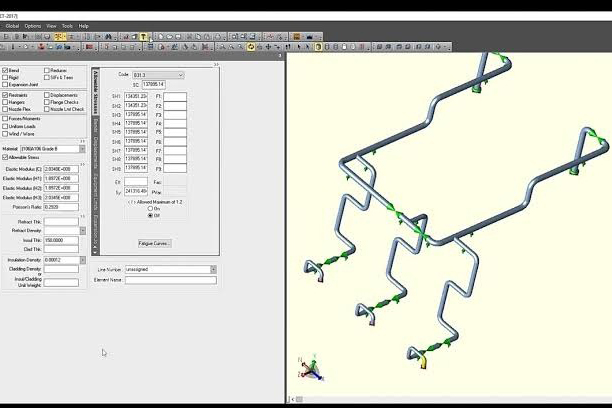

CAESAR

CAESAR is the industry standard for pipe stress analysis, letting you build, assess and report on piping systems of any size or complexity in accordance with more than 35 international piping code standards and many environmental and equipment guidelines. Integration with CAD design packages lets you quickly import models, reducing risk for errors and costly iteration time between CAD and Stress Analysis divisions.

CAESAR makes it easy to input and display all the data needed to accurately define a piping system analysis model.

The CAESAR input graphics module makes quick work of developing analysis models while clearly indicating areas of concern.